Vibrating table for concrete testing

Vibration table is an important machine in the preparation of concrete molds used in the products considered to be produced by using aggregate and in constructions. Products in the market were examined and common characteristics were determined. The table sizes of the vibration tables with the smallest and largest dimensions are 400x380x450 mm and

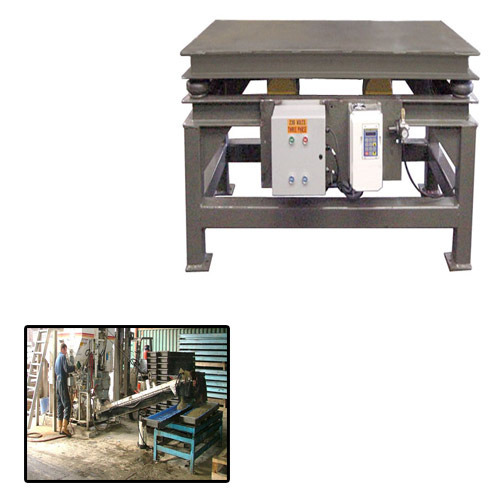

2500mm x 1000mm Concrete Vibrating Table Electrotech Drives

Vibration equipment includes a vibration table with rotating shafts for producing vibrations and used in casting concrete blocks for e.g. paving and erection of walls. These vibration tables are normally made of cut-out, welded steel parts that after welding constitute the main part of the vibration table, making such vibration tables costly and resulting in relatively great waste of material.

Vibrating Tables Settle, Densify, Compact, Vibration Testing

Deca Vibrator provides a comprehensive line of vibration equipment for large precast concrete tables. You can rely on our equipment to provide consistent vibration for precast tables, and you can rely on decades of experience in the industry to help you find a precast concrete casting solution that works for your application.

VIBRATING TABLE OF CONCRETE GEOTECHNICAL

Watch how VIBCO USP-900 Vibrators on female pin brackets help to improve the efficiency and quality of precast concrete burial vault production. The VIBCO USP-900 is precast concrete industry favorite because it is a workhorse and has great portability between forms. VIBCO's Model USP-900 is a 115 volt single phase motor with low amperage draw.

vibrating table for concrete molds roller mixer manufacturers in ahmedabad india

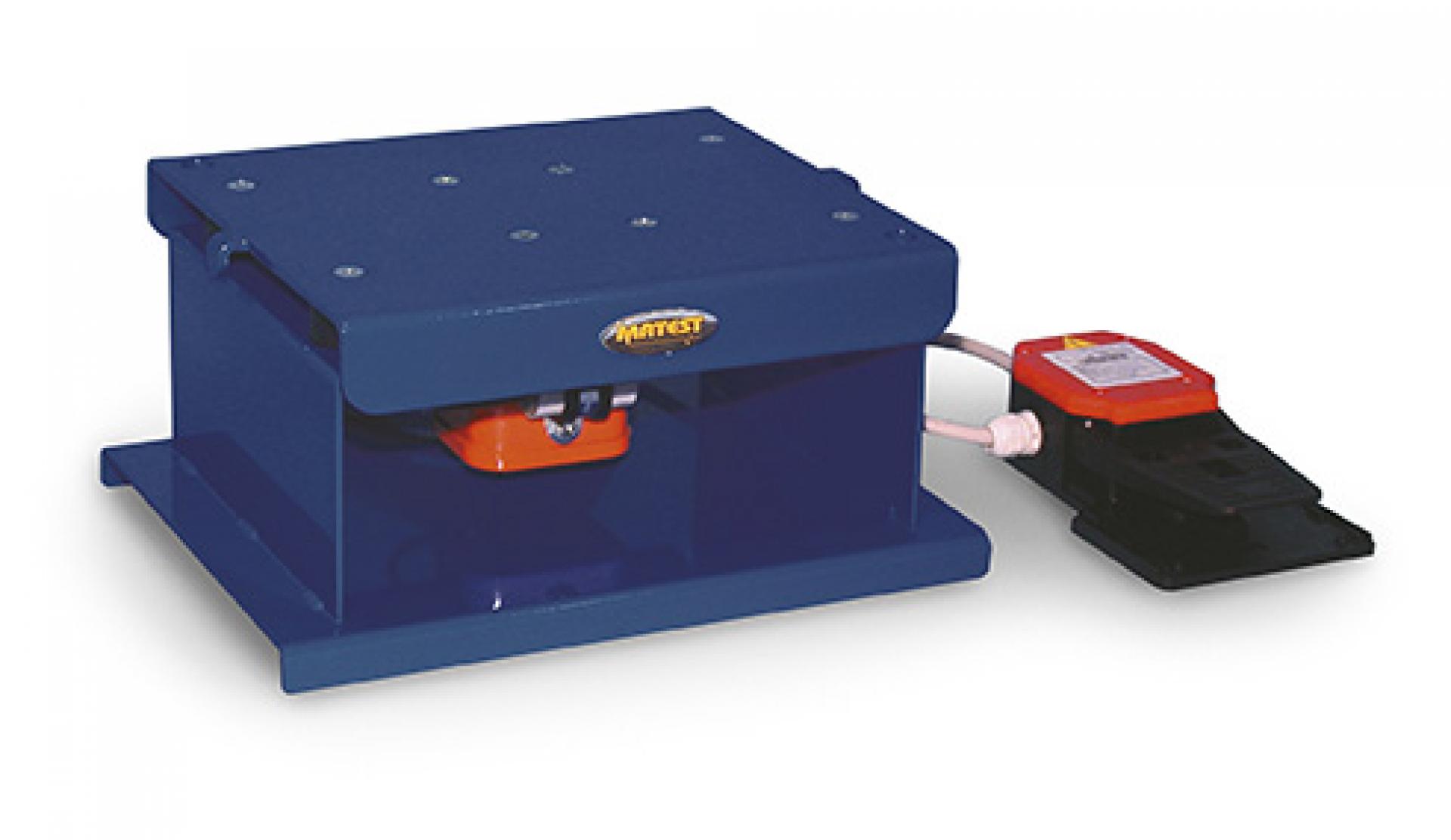

Concrete Vibrating Table is used for consolidating fresh concrete when forming cylinder and beam molds. The unit has a 20x20in (508x508mm) large platform with a load capacity of up to 300lb (136kg).

Newly fabricated vibrating table for concrete moulds Concrete countertops, Table, Countertops

Vibrating tables are commonly used in many different industries, including: Construction and building: used to settle and compact concrete mixtures within forms and molds, ensuring a strong and even finish. Labs: Testing the durability and strength of materials, such as ceramics, by subjecting them to vibrational stress. Testing products for.

Concrete Vibration table Vibration table Vibro Table GlobMarble

There are also a number of variable speed vibration motors out there, but most are quite large (more for vibrating big concrete molding tables) Ideally I think a 12"x24" vibrating table would be perfect for my shop, but the only pre-built model I've found is over $800, which is horribly over priced.

Concrete Vibrator Table at Rs 70000 वाइब्रेटिंग टेबल in Indore ID 13692457973

1 1 1 Inthis project the proposed concept is to replace the manual work of removing air bubble from concrete block by providing vibrations to the concrete block with the help of cam and motor arrangement..

Vibrating Table for Concrete Concrete Vibration Testing and Tests

With NetterVibration 's standard vibrating tables, the processes at your plant or facility will be more efficient, substantially reducing your costs. Standard vibrating tables can be used for a wide range of applications such as compacting bulk materials to reduce shipping cost and de-moulding cast parts quickly and without damaging the product.

Vibrating Table 1250 x 625mm for 8 cube moulds, 240V Concrete Impact civil engineering

The Concrete Moulds Vibrating Tableis used to compact concrete cube mould, cylindrical Mould Beam Mould etc, Breakers are put around Vibrating Table size like 600mm 24inch, 500mm 20inch boundaries to prevent moulds from rolling off the top of the table while it is in use.

Vibrating Table for Concrete LabQuip Ltd Testing Equipment Suppliers

Products Concrete Vibrators & Finishing Equipment Concrete Vibrating Tables Concrete Vibrating Tables Applying proper vibration is the ideal way to prevent common problems found in concrete elements, such as bugholes, honeycombing, and cold joints.

Concrete Mold Vibrating Platform Shaking Table Buy Vibrating Shaking Table,Vibrating Table

Vibratoring tables are machines which are used to vibrate concrete moulds or forms, allowing the mixture to settle and eliminate air bubbles trapped inside. There are different types of Table vibration machines such as internal vibrators, surface vibrators or external vibrators, and form vibrators.

Culture Stone Concrete Vibration Table Machine 25mm Amplitude Brick Vibration Platform

GlobMarble offers affordable, durable and effective vibrating tables to suit any industrial or construction application for a stronger concrete and a better finish. Concrete Vibrating table dimensions: 48x24x36-height (1219 x 609 x 914mm) LxWxH. Included variable speed control. On/Off switch. CVM 35 Motor - vibration force 700lbs (350 kgs)

Vibrating Table 600 x 400mm for 2 cube moulds, 240V Concrete Impact civil engineering

Vibration equipment includes a vibration table with rotating shafts for producing vibrations and used in casting concrete blocks for e.g. paving and erection of walls. These vibration tables are normally made of cut-out, welded steel parts that after welding constitute the main part of the vibration table, making such vibration tables costly and resulting in relatively great waste of material.

How to Make an Inexpensive Concrete Vibrating Table GlobMarble

In connection with casting concrete blocks for e.g. paving and erection of walls, a vibration equipment consisting of a vibration table with mounted rotating shafts for producing the vibration is used. Such vibration tables are normally made of cut-out, welded steel parts that after welding constitute the main part of the vibration table.

Concrete Vibration / Vibratory Table For Moulds Buy Concrete Vibratory Table,Concrete

Table vibration is commonly found on big board or large pallet concrete products machines. It uses vibrators which are connected to impact bars, these bars strike the bottom of the production pallet to create vibration throughout the product. It is inherently inefficient due to the random motion, which leads to poor height control and non.